STX-SET Series

Happiness for the cells and Success for users. 22 years technology into STX. To support successful cell culturing with new features. “STX” is our answer to the optimized incubating environment.

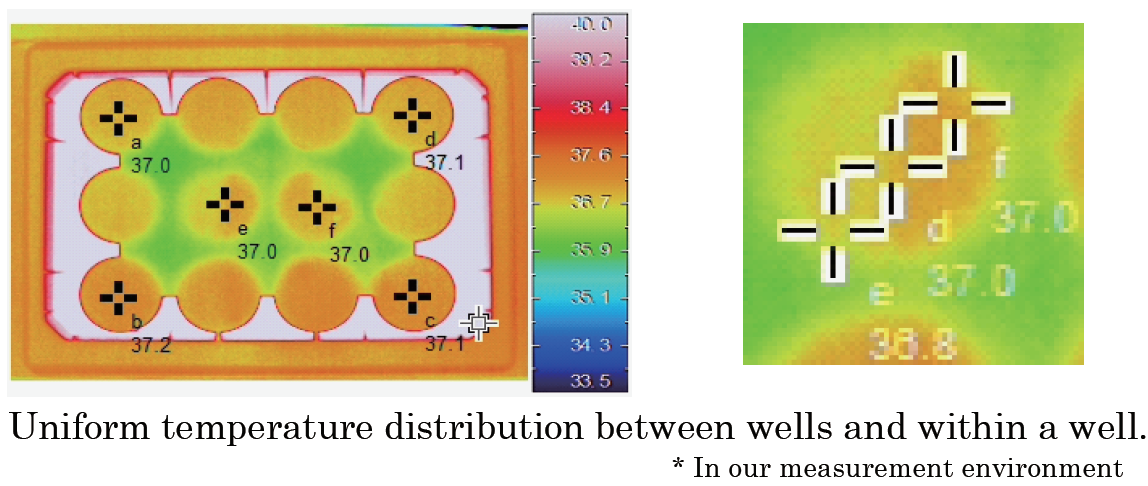

Accurate and uniform temperature control

TOKAI HIT Heating Quality

Tokai Hit’s original Top Heater is proven to distribute heat uniformly within the Chamber

regardless of the type of vessels.

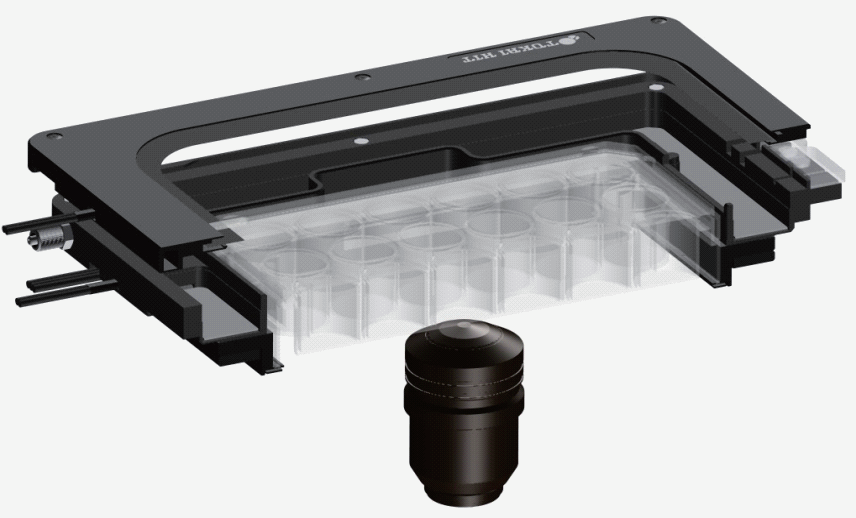

No interference by objective

With unique Top Heater Heating Time regulation, the bottom of Chamber is access-free for variety of objectives. (No metal plate at the bottom.)

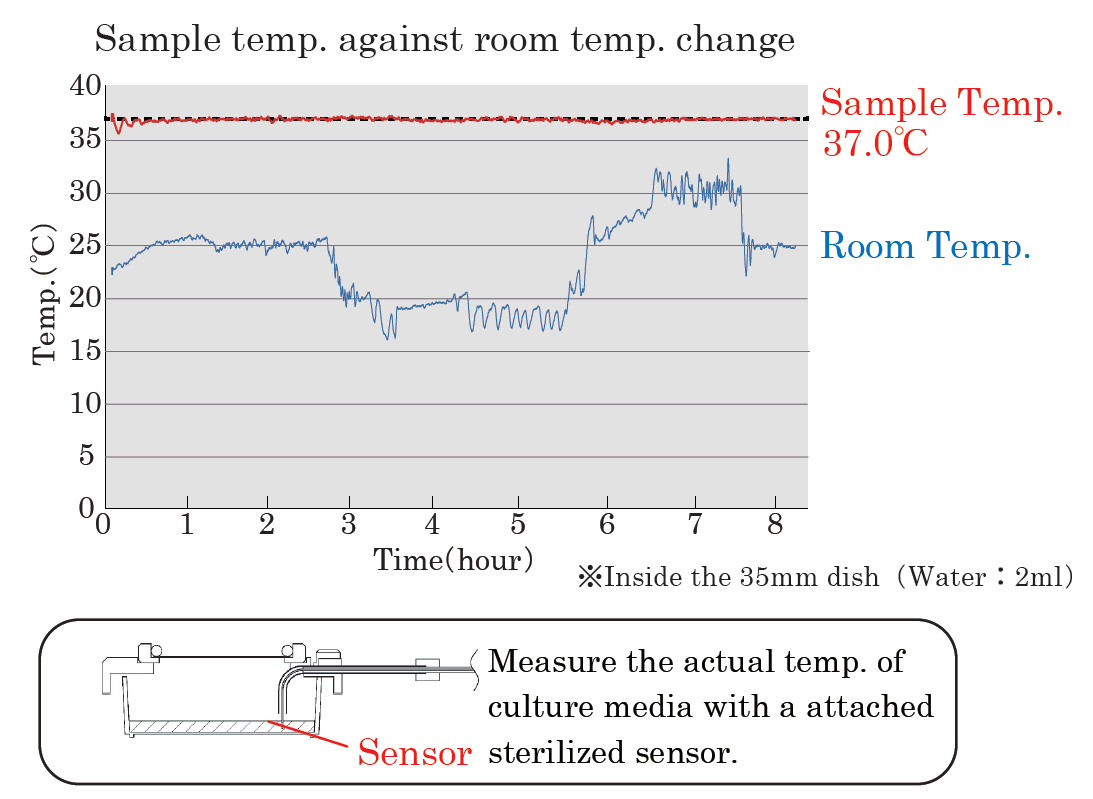

Real-time Sample Feedback Regulation

Sterilized temperature sensor and magnetic lids make it easy to measure

the temp. of culture media upon research needs.

The controller regulates the heater based on the sensor signal to keep sample at the target temp. accurately.

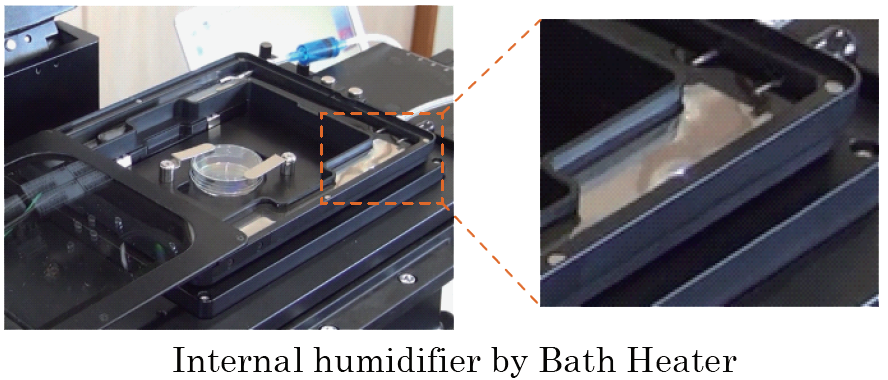

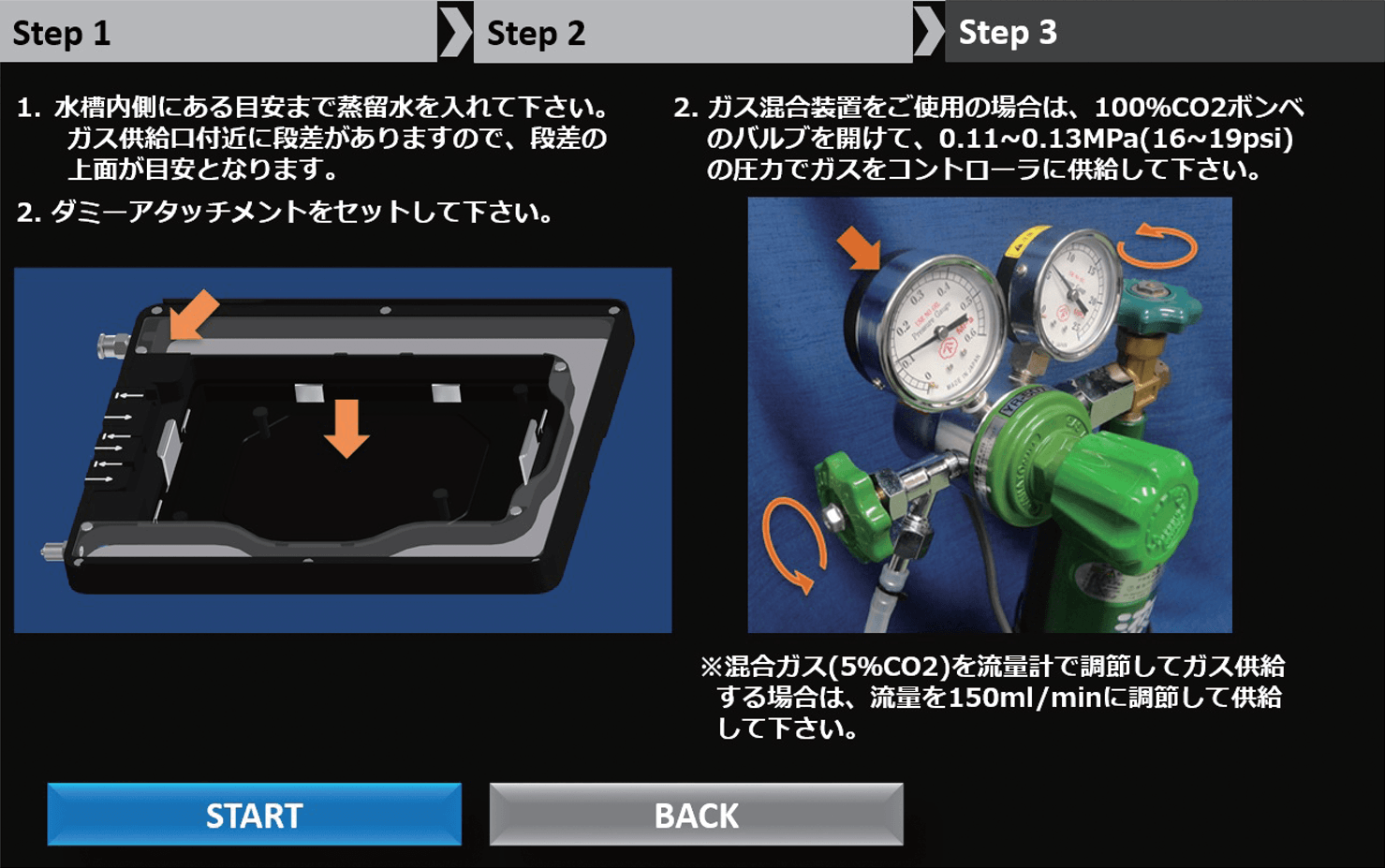

Apply Internal Humidifier to keep high humidity condition during the imaging

Keeps high humidity inside the chamber by heating the distilled water in the Bath Unit.

Internal Humidifier minimizes the change in concentration of media by keeping the humidity inside the chamber.

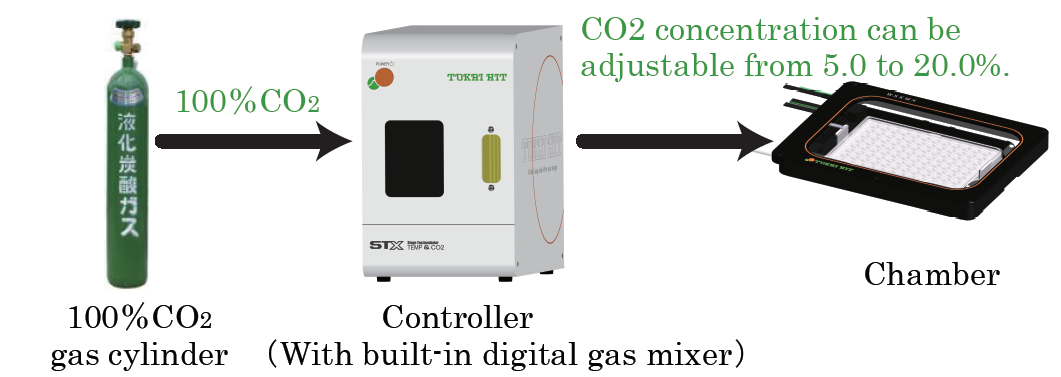

Stable CO2 environment

The controller mixes 100%CO2 gas and the surrounding air automatically. Stable gas concentration inside the Chamber is obtained by keep sending the mixed gas to the Chamber.

(※In case of controller with a built-in digital gas mixer)

Stress-Free Quality

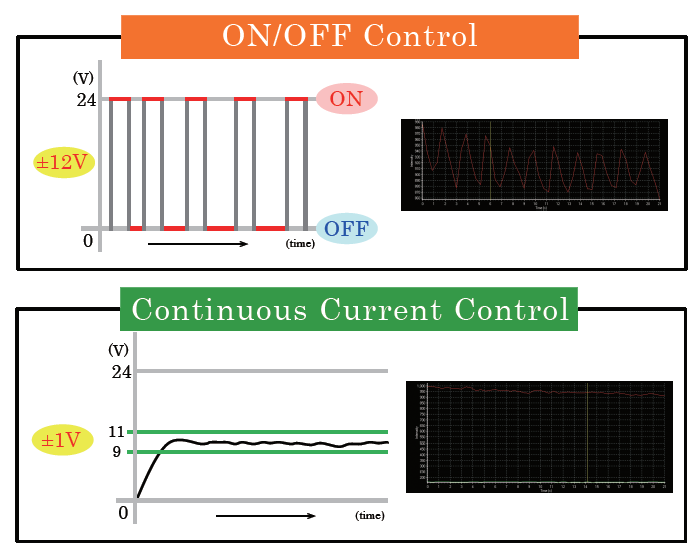

Prevent the focus drift

In addition to PID control, Continuous Current Control minimizes the focus drift generated by thermal expansion and it also prevents light intensity change compared to the conventional ON/OFF control.

STX-APP (Software)

Simple operation of GUI will assist to visualize the preparation to setting and lead your cell culture to success.

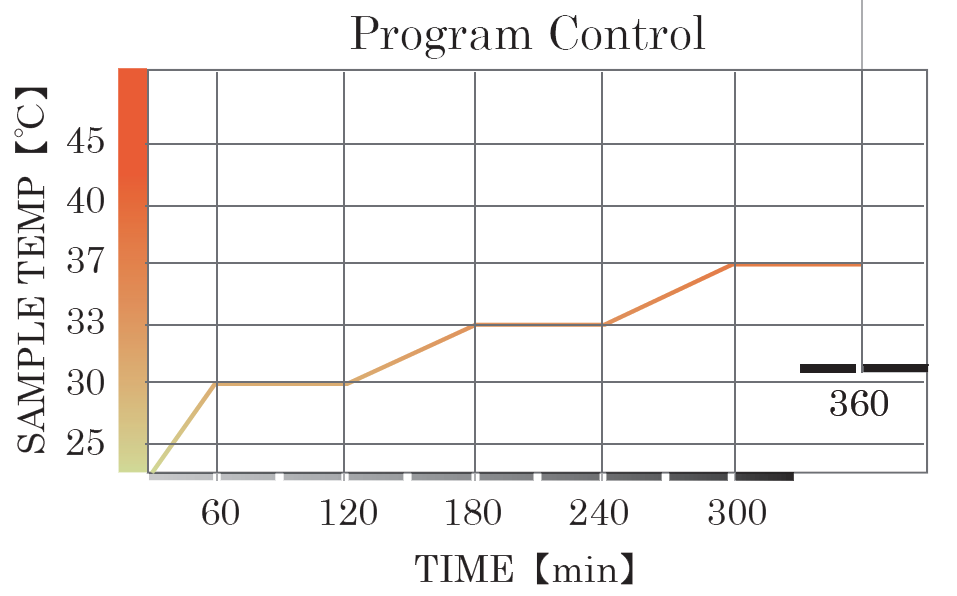

Programmable Control

The system includes the software to program temp. and CO2/O2 concentration

as this function allows to expand the variety of experiment.

Screen Capture

Captures the PC screen to transfer images to smart-phones and tablets.

Enables to see the image at home. *PC must be connected with internet.

Data Logging

Logs the temperature of each heaters, sample temperature and gas concentration

and saves the data in CSV format.

Specification

| STXG with built-in gas mixer | STXF with analog flowmeter | |||

|---|---|---|---|---|

| Temperature | Temperature control | PID control | ||

| Increments | 0.1℃ by digital switches | |||

| Setting method | Touch Panel or PC | |||

| Possible temp. setting range* | SAMPLE TEMP | 30℃~40℃ | ||

| TOP HEATER | 10℃~65℃ | |||

| BATH HEATER | 10℃~50℃ | |||

| STAGE HEATER | 10℃~50℃ | |||

| LENS HEATER | 10℃~45℃ | |||

| Rise time | 10 minutes to reach 50℃ | |||

| Accuracy | Within ±0.3℃ at each heater surface(in our terms and conditions) | |||

| Sensor | Pt 100 | |||

| Humidity | Humidification control | Forced humidification by heating Bath Unit | ||

| Condensation prevention | Top Heater equipped with glass heater | |||

| Gas | CO2 concentration range | 5%~20% | ー | |

| Control method | PID control | Precision needle valve | ||

| Accuracy | Within ±0.1% | Within±2% FS | ||

| Gas type | 100% CO2 | 5%CO2 | ||

| Input gas pressure | 0.1Mpa~0.15MPa | |||

| Output gas pressure | 160 ml/min | 75 ml/min~ 250 ml/min | ||

| Power source | 100 V~240 V AC ±10% 50/60Hz | |||

| Maximum power consumption | 110W | 90W | ||

Newsletter

Be the first to get all the information about new products in our range and find out the latest research results in microscopy in our free newsletter.